3rd semester project

Fluid Furniture

Intro

The production, use and delivery of many products often goes hand in hand with environmental pollution. Plastic production is increasing, waste mountains are growing and the longevity of products is decreasing.

The term „biodesign“ is becoming all the more important. In addition to innovative low-emission production processes, the optimization of recycling systems and the simple avoidance of plastic waste, compostable plastics and natural materials are gaining in importance.

The goal became to design an innovative compostable everyday product and to look deeply into ecological materials to show that product design does not have to exist at the expense of the environment.

My idea

to construct a chair where the timing of composting can be determined by its owners.

Helios Support

water soluble / 3d-printable PVA Material

• Good solubility

• Excellent thermal stability

• Biodegradable once dissolved in water

• Safe dissolution in tap water

• Can be disposed of in the kitchen sink, or household drain with an excess of water

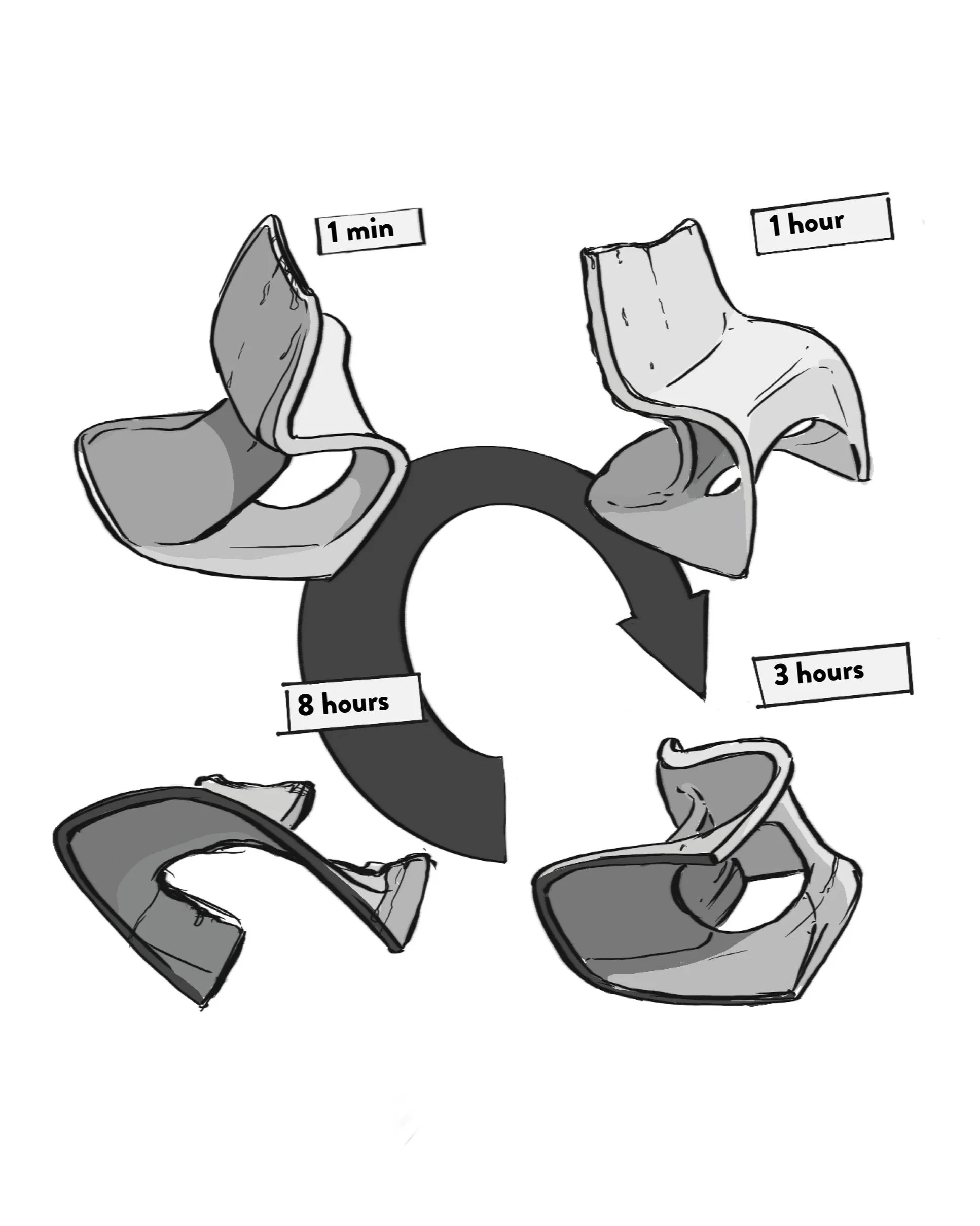

Material Test

The material test confirms what was already suspected. A small drop of water does not yet cause the material to decompose. However, as soon as it is in constant contact with water, the decomposition process can be followed. If you pull the part out after a few minutes, it feels slippery and is more elastic.

After about 3 hours, there is not much left of the 3d printed plate. Initially, I was afraid that the process cannot be controlled. However, the gyroid structure provides an ideal distribution of the water masses, which leads to an even and relatively fast composting.

Form finding

At the beginning, I was not sure whether an organic or geometric design language would be more suitable for such a concept. In the end, I decided in favor of the organic design. Not only does the jumped shape round off the concept, but it also simplifies the distribution of water when filling.

Visually, I was inspired by the absolute design classic, the Panton chair, because its shape provides optimum water distribution. As the material is not as stable as other filaments, I integrated a support designed to make the product more durable.

Nevertheless, many shapes are possible as long as they can be 3D printed and can support the weight of a human body. This means that it is possible to realize completely different designs. You could also produce only single parts of a chair with such a process to achieve at least partial compostability.

Once the owners decide they no longer need the chair, it is filled with water. The gyroid infill structure ensures harmonious water distribution. As soon as the water hits the water-soluble filament, the chair starts to decompose. The whole process takes several hours but can be done in a bathtub or shower. The remains are released into the cast and the stool is composted.